Reverse Engineering of a Pelton Wheel - Part One: Alignment

Introduction

Reverse engineering is the creation of CAD surfaces from scan data.

In most cases, a scanner provides the point clouds used to create a 3D mesh. Then, CAD surfaces can be computed from the 3D mesh and a polyline network. CAD surfaces can be exported in IGES or STEP format and further used in other software for Computer Aided Manufacturing (CAM), Finite Element Analysis (FEA) or for comparison and inspection.

This exercise is part of full workflow that shows how to convert a point cloud into a CAD model. The steps below give a global description of the full process:

Align the part thanks to the extraction of geometric features on a mesh created from the point cloud - this is the part covered in this exercise

Clean the mesh so that it can be replicated by symmetry and rotation

Create an automatic network of polylines and edit this network in the required areas to create the surface

Exercise overview

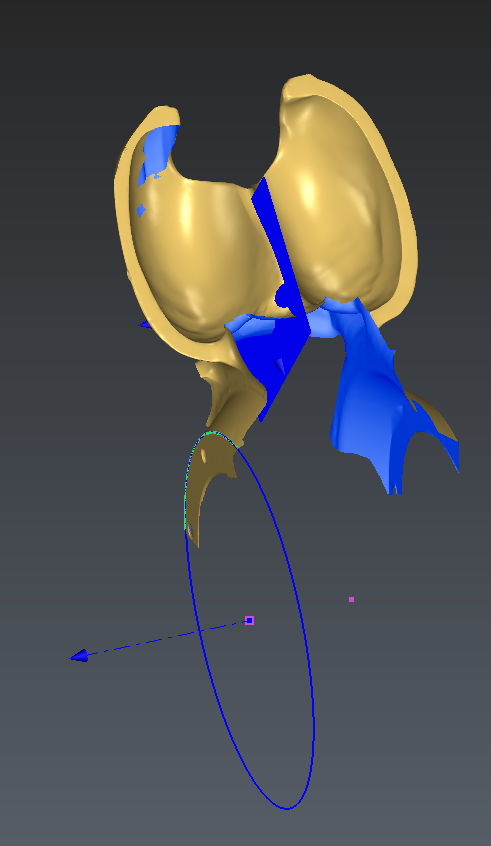

As shown in the figure below, the coordinate system in which the point cloud was measured was a default one where the Z, Y or X axis do not correspond to anything in the part.

This exercise will show how to align:

The X axis so that it corresponds to the rotation axis of the wheel,

The Y axis so that it is perpendicular to the front plane of the wheel

The origin so that it corresponds to the rotation axis in the middle of the blade

To do so, the following steps are required:

Mesh the point cloud

Extract the X axis on the side of the wheel

Extract the rotation axis

Calculate the middle plane

Compute the origin

Extract the Y axis in front of the blade

Apply the alignment

The file used in this tutorial in PeltonWheel_Reverse_1-Alignment.3dr

The file can be downloaded on Cyclone 3DR - Downloads page.

Top view of the point cloud before alignment

Meshing the point cloud

Select the point cloud and launch the 3D Mesh command.

Choose the 2 steps meshing strategy with an average distance of 20 mm. A default value of approximately 60 mm for hole detection is proposed.

Hit OK to create a rough mesh which contains the right topology and continue with the second step of the process which will refine the mesh.

In this refine step, select the following parameters:

Select the Refining method as Refine Mesh from Cloud Interpolation

Select the Mesh generation method as Refine with deviation error

Default parameters for Deviation error, Maximum number of triangles and Minimum triangle size are calculated based on the rough mesh. These apply well here so no need to modify them.

Check the Distance parameter and keep the default value so that sparse point do not affect the results

Uncheck the options to apply a local reorganization

Uncheck the options to filter based on the angle on scanning direction

Finally, choose the option to refine the free border

Step 1 meshing to get a smoothed and accurate mesh from the point cloud

Step 1 meshing to get a smoothed and accurate mesh from the point cloud

Step 2 meshing to get a smoothed and accurate mesh from the point cloud

From this mesh, a lot of geometric data can be extracted for defining a precise alignment.

Extracting the X axis

The X axis that we want to define is facing laterally to the blade.

Launch the Region Grow Plane tool and pick a point on the side of the wheel (the one which is less damaged!).

As we need only the plane information, you can leave unchecked 'Extracted Points' and 'Label' in order to keep only the 'Plane' object (the center point and the normal direction must be unlocked).

Plane extracted on the side of the wheel

Extracting the rotation axis

The rotation axis will be extracted on the curved circular area that we can see on the mesh, at the end of this plane.

To extract the circle, we will first extract the feature line:

Select the mesh and launch the Single Breaking Line command

Choose the option Only concave or only convex

Pick 2 points at the begin and end of the curved area as shown below with the 2 red balls

Extraction of the feature line

A polyline is created between these 2 red balls that follow the curved area of the mesh, i.e. the circle that we are looking for.

We will now create the axis that we are looking for by best fitting a circle on this polyline:

Select the polyline and launch the Best Circle command

Force the normal to be perpendicular to the previously measured plane:

Lock the normal by clicking on the corresponding lock icon

Select the normal with the option Direction of a component

Pick the plane previously created

Keep only the circle as outputs

Hit OK

The circle best fitting the extracted feature line and aligned with the side plane

Display Axis and center point of geometrical features

Note that you can display by default the axis and the center of each geometrical in the Geometrical Feature settings

Calculate the middle plane

The middle plane that we are looking for is in the middle of the wheel and parallel to the side plane: its mathematical definition is the best symmetry plane that is parallel to the side plane.

In order to calculate a symmetric plane, an initial one must be created. This initial plane should be parallel to the side plane and close to the middle.

The following process is therefore required:

Duplicate the side plane with a Copy and Paste operation and hide the initial side plane.

Edit the newly created plane to approximate the middle plane

Select the plane and launch Edit Plane or double click or use the contextual menu (right click) on the duplicated plane

Drag the plane using preferably the red and blue arrows as shown below so that it is close to the expected result

Hit OK

Calculate the best symmetry plane

Select the approximated plane and the mesh

Launch the Best Symmetry Plane command

Define constraints and choose the option to Disable rotations (Only parallel plane)

Hit OK

Translating the plane to an approximate position

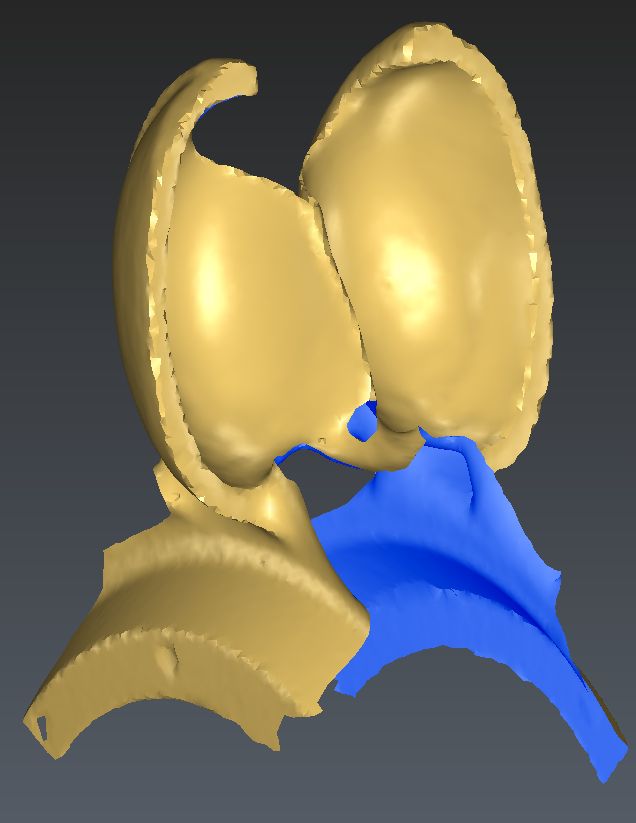

Best symmetric plane calculated (in blue) from the approximated one (in red)

Computing the origin

The origin of the alignment that we are looking for is actually the center of the circle previously calculated projected onto the symmetry plane.

The steps to create the origin are the following ones:

Create the point at the middle of the circle using the command Point and the option Midlle / Center or use other option to select the existing center if displayed by default (see in the Geometrical Feature settings).

Select the point that was just created and the Symmetry plane and launch the Projection command

Choose the Shortest distance option and hit OK, Exit

You can rename the projected point to Origin.

Projected point on the symmetry plane

Projected point on the symmetry plane

Extracting the Y axis in front of the blade

The Y axis that we are looking for is facing in front of the blade.

The procedure to create it is as follow:

Launch the Region Grow Plane command

Hit 2 points (or more if needed) in front of the blade of both sides and validate with OK, Exit (if necessary adjust the extraction tolerance to 5or 10 mm)

Plane extracted in front of the blade

Applying the alignment onto the mesh

Every component previously created now allow to apply an alignment onto our data.

Select all the data and launch the Geometric Registration command:

The source point of the Origin will be the point named Origin

The main axis is X and is defined on the side plane

The second axis is Y and is defined as the front plane

Hit OK

The data is now aligned with X, Y and Z and the origin of the coordinate system is on the revolution axis of the wheel